NEWBASE Electric Bus Air Conditioner: 8 Pioneering Technologies Redefining Passenger Comfort & Safety

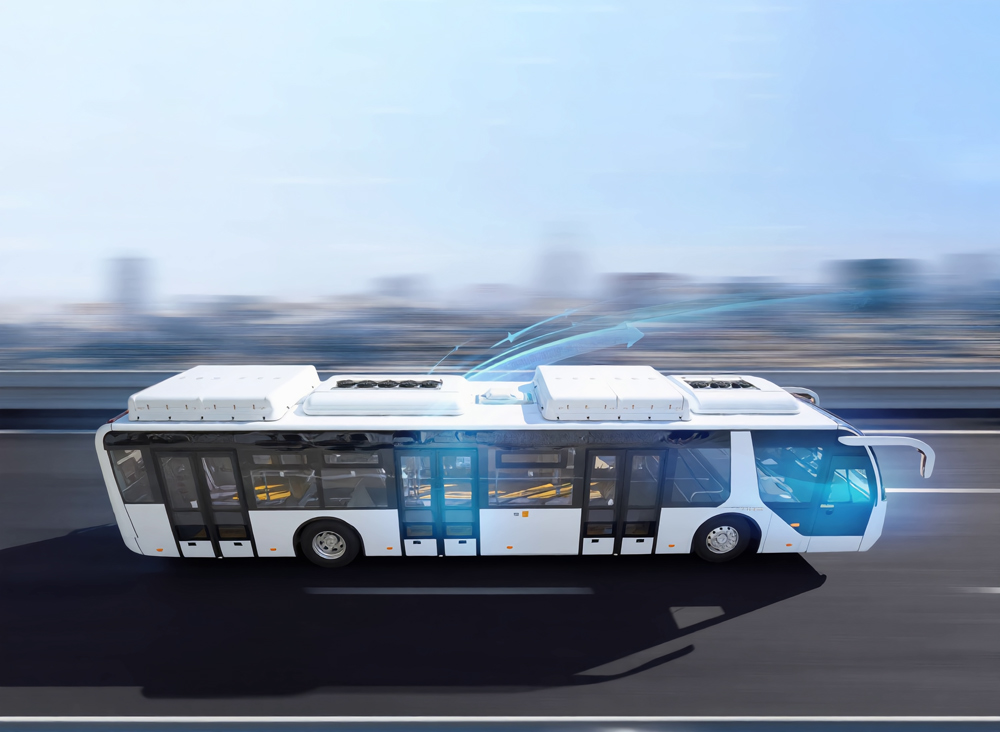

At NEWBASE, we engineer electric bus air conditioning systems that set global benchmarks for innovation, efficiency, and reliability. Our Electric Bus Air Conditioner integrates eight groundbreaking technologies designed to deliver uninterrupted comfort, energy savings, and industry-leading safety—even in the most demanding urban transit environments.

Core Technologies & Advantages

- Global-First Uninterrupted Cooling (Post-Ignition Off)

- Patent-Pending Technology: Maintains cabin temperature for 30+ minutes after engine shutdown, using kinetic energy recovery and battery-powered operation. Ideal for bus stop layovers and emergency cooling.

- Aerospace-Grade Fiberglass Housing

- Triple-Layer Insulation: Reduces thermal leakage by 45% vs. conventional metal casings. UV-resistant coating ensures zero degradation under prolonged sun exposure.

- Helical Copper Tubes & Hydrophilic Aluminum Fins

- Enhanced Heat Exchange: Spiral-grooved copper pipes increase refrigerant contact area by 30%, while hydrophilic-coated aluminum fins repel moisture, preventing frost buildup.

- Subcooling Condenser Design

- Energy Efficiency Boost: Overcooling refrigerant before expansion raises COP (Coefficient of Performance) by 20%, cutting power consumption without compromising cooling capacity.

- World-Class Compressor Partnerships

- Powerhouse Performance: Equipped with Danfoss/Sanden scroll compressors for rapid temperature pull-down (-5°C to +30°C in <15 mins) and stable operation at 55°C ambient.

- Whisper-Quiet EC Fan Motor

- <55dB Operation: Electronically Commutated (EC) fans reduce noise pollution by 60% while improving airflow efficiency by 25%. MTBF exceeds 10,000 hours.

- Flame-Retardant Wiring Harness

- V-0 Certified Materials: All electrical circuits use halogen-free, 960°C-resistant cables. Auto-shutdown triggers if temperatures exceed 85°C.

- Dual-Layer Safety Circuit Board

- Fail-Safe Architecture: Patented dual-PCB design isolates high/low-voltage components, preventing short circuits. Built-in self-diagnostics for real-time error detection.

Why Transit Operators Choose NEWBASE

- Cost Efficiency: 30% lower lifecycle costs due to durable components and reduced maintenance.

- Eco-Compliance: Meets EU ELV, RoHS, and CALGreen standards for zero hazardous substances.

- Smart Integration: Compatible with telematics systems for remote diagnostics and predictive maintenance.

- Customization: Modular designs fit 8–18m electric buses, with options for roof-mounted or split-type units.

Real-World Impact

- City Transit: Maintains 22°C cabin temperature for 45 mins post-shutdown during peak-hour delays.

- Intercity Routes: Sustains -15°C freezing capacity at 40°C desert ambient conditions.

- Safety First: Zero fire incidents reported across 50,000+ installed units globally.

Join the Electric Mobility Revolution

NEWBASE Electric Bus Air Conditioners are trusted by leading operators in 35+ countries. From scorching highways to congested urban routes, our systems ensure passengers arrive refreshed—every ride, every time.

NEWBASE: Where Innovation Meets Sustainable Transit.

Technical Snapshot

| Feature | Performance |

|---|---|

| Cooling Capacity | 28,000–45,000 BTU/hr |

| Power Input | 3.2–5.8 kW (DC 400–800V) |

| Weight | 185–320 kg (lightweight variants) |

| Certifications | E-Mark, ISO 16949, UN R10 |

Engineered for the Future of Mass Transit