Modulo di potenza per la refrigerazione 3 in 1

NB-015C5A-CPY04 Modulo di potenza per la refrigerazione 3-in-1 - Controllo intelligente della catena del freddo per veicoli commerciali elettrici...

Convertitore CC/CC per veicoli elettrici: Panoramica del prodotto

Introduzione

Nei veicoli elettrici (EV), il pacco batterie ad alta tensione immagazzina energia in corrente continua (DC) inadatta ad alimentare i sistemi a bassa tensione (ad esempio, illuminazione, infotainment, strumentazione). Il convertitore CC/CC colma questo divario riducendo in modo efficiente la corrente continua ad alta tensione (tipicamente 300-800 V) a 12 V CC, garantendo un'alimentazione affidabile per i sistemi ausiliari e mantenendo la compatibilità con le architetture elettriche automobilistiche tradizionali.

Funzioni e caratteristiche principali

Architettura tecnica

Vantaggi

Applicazioni

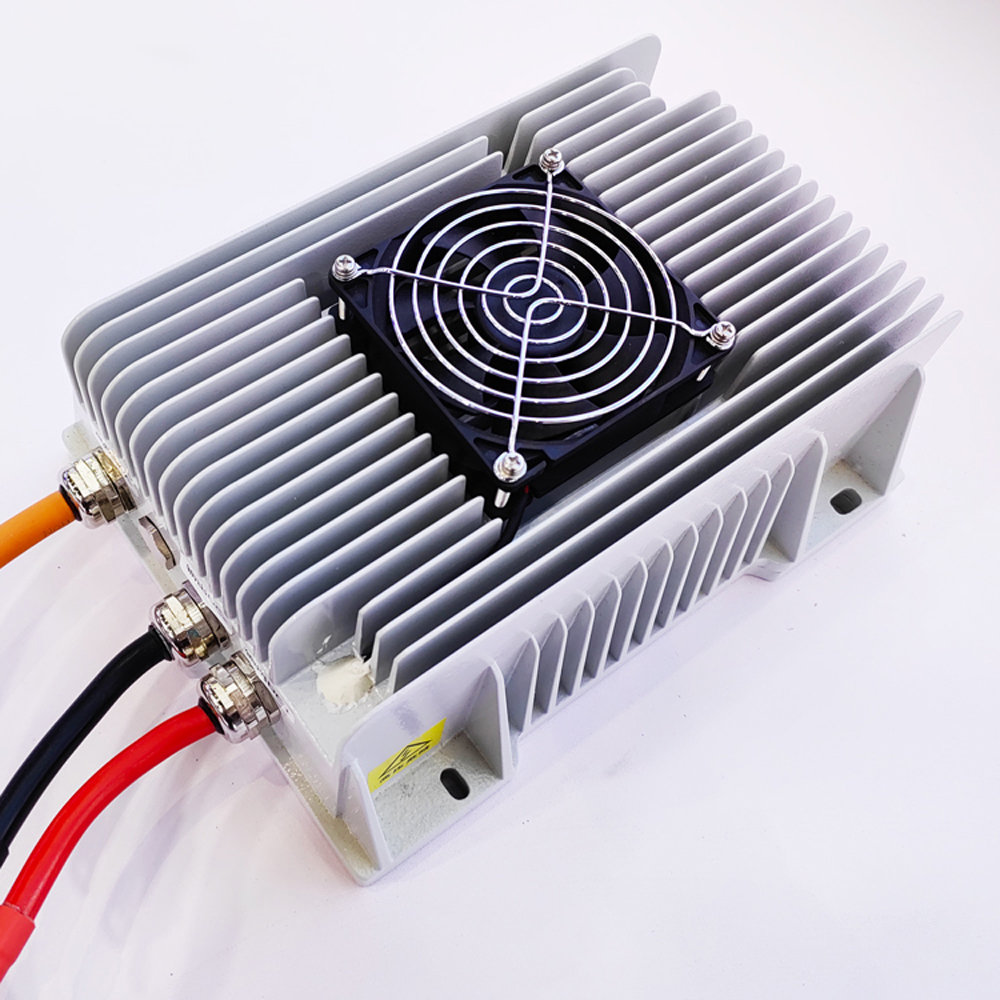

| Convertitore di potenza CC - CC |

|---|

| Dati tecnici |

| Tensione di ingresso: 185V~850V (personalizzata) |

| Potenza: 1,2KW/2KW/3KW |

| Corrente di dispersione statica della batteria: ≤10mA |

| Controllo degli ingressi: controllo dell'abilitazione hardware, comunicazione CAN |

| Cavo LV, tensione di tenuta 700~400Vdc |

| Tensione nominale di uscita: 27,5 ± 0,2 Vdc, Corrente massima di uscita: 110 A |

| Tempo di avvio della tensione di uscita: entro 6s (a carico nominale) (ingresso 540Vdc, uscita 27,5Vdc, tempo di prova a carico nominale) |

| Potenza di uscita: 3000W (MAX) |

| Perdita statica Corrente ≤10mA |

| Temperatura di funzionamento: - 40°C - 65°C |

| Resistenza di isolamento ≥20MΩ/100Vdc |

| Livello di protezione: IP67 |

| Requisiti del cavo - Cavo HV, tensione di resistenza 1500Vdc; |

NB-015C5A-CPY04 Modulo di potenza per la refrigerazione 3-in-1 - Controllo intelligente della catena del freddo per veicoli commerciali elettrici...

Titolo: NB-015C5A-CPY06 Modulo di controllo termico EV all-in-one - intelligente, compatto e ad alta efficienza per la catena del freddo...

Unità di refrigerazione per furgoni: NBESR1000A - Tecnologia di raffreddamento avanzata per la moderna logistica della catena del freddo Come...

In un ambiente logistico in rapida evoluzione, un controllo affidabile della temperatura non è solo una caratteristica, ma una necessità. NEWBASE...

Unità di raffreddamento per autocarri refrigerati NEWBASE: Progettata per un raffreddamento uniforme, una qualità dell'aria e un funzionamento sostenibile...

Furgone refrigerato elettrico: NBESR1000A - Il futuro della logistica sostenibile della catena del freddo Come...