Módulo de potência de refrigeração 3 em 1

NB-015C5A-CPY04 Módulo de potência de refrigeração 3 em 1 - Sistema de refrigeração inteligente...

Ar condicionado com bomba de calor inversor CC completo, adequado para autocarros elétricos puros de 6 a 12 m, autocarros híbridos e autocarros com célula de combustível (plataforma básica).

| Modelo Básico | NBEAC-21 | NBEAC-24 | NBEAC-30 | NBEAC-34 |

| Forma Estrutural | Montado no tejadilho Integrado | |||

| Comprimento do Barramento Aplicável (m) | 6~7 | 7~8.5 | 9~10 | 10~12 |

| Capacidade de Refrigeração (KW) | 18 | 26 | 30 | 32 |

| Capacidade de Aquecimento (Bomba de Calor) (KW) | 20 | 28 | 36 | 38 |

| Volume de Fluxo de Ar do Evaporador (M/h³) | 3200 | 3200 | 4800 | 7200 |

| Volume de Fluxo de Ar do Condensador (M/h³) | 4800 | 6000 | 8000 | 1000 |

| Número do Compressor | Individual | Simples/Dual | ||

| Fluido Refrigerante | R407C/410A | |||

| Tamanho (C*L*A, mm) | 2610*1600*270 | 2500×1920×280 | 2750*1920*280 | 3000*1920*270 |

| Peso Unitário (kg) | 150 | 230 | 250 | 275 |

Integração de sistema de gestão térmica da bateria e ar condicionado montado no tejadilho (integração compacta)

Adequado para autocarros elétricos puros, autocarros híbridos e autocarros com célula de combustível equipados com baterias refrigeradas a líquido, atendendo às necessidades de arrefecimento/aquecimento do ar condicionado e arrefecimento/aquecimento da bateria.

| Modelo Básico | NBEAC-21-T | NBEAC-24-T | NBEAC-30-T | NBEAC-34-T |

| Forma Estrutural | Montado no tejadilho Integrado | |||

| Comprimento do Barramento Aplicável (m) | 6~7 | 7~8.5 | 9~10 | 10~12 |

| Capacidade de Refrigeração (KW) | 18 | 26 | 30 | 32 |

| Capacidade de Aquecimento (Bomba de Calor) (KW) | 20 | 28 | 36 | 38 |

| Capacidade de arrefecimento do lado da bateria (KW) | 3/5 | 3/5 | 3/5 | 3/5 |

| Capacidade de arrefecimento do carregamento do lado da bateria (KW) | 5 | 8 | 8 | 8 |

| Volume de Fluxo de Ar do Evaporador (M/h³) | 3200 | 3200 | 4800 | 7200 |

| Volume de Fluxo de Ar do Condensador (M/h³) | 4800 | 6000 | 8000 | 1000 |

| Número do Compressor | Individual | Simples/Dual | ||

| Fluido Refrigerante | R407C/410A | |||

| Tamanho (C*L*A, mm) | 2610*1600*270 | 2500×1920×280 | 2750*1920*280 | 3000*1920*280 |

| Peso unitário(kg) | 180 | 260 | 250 | 275 |

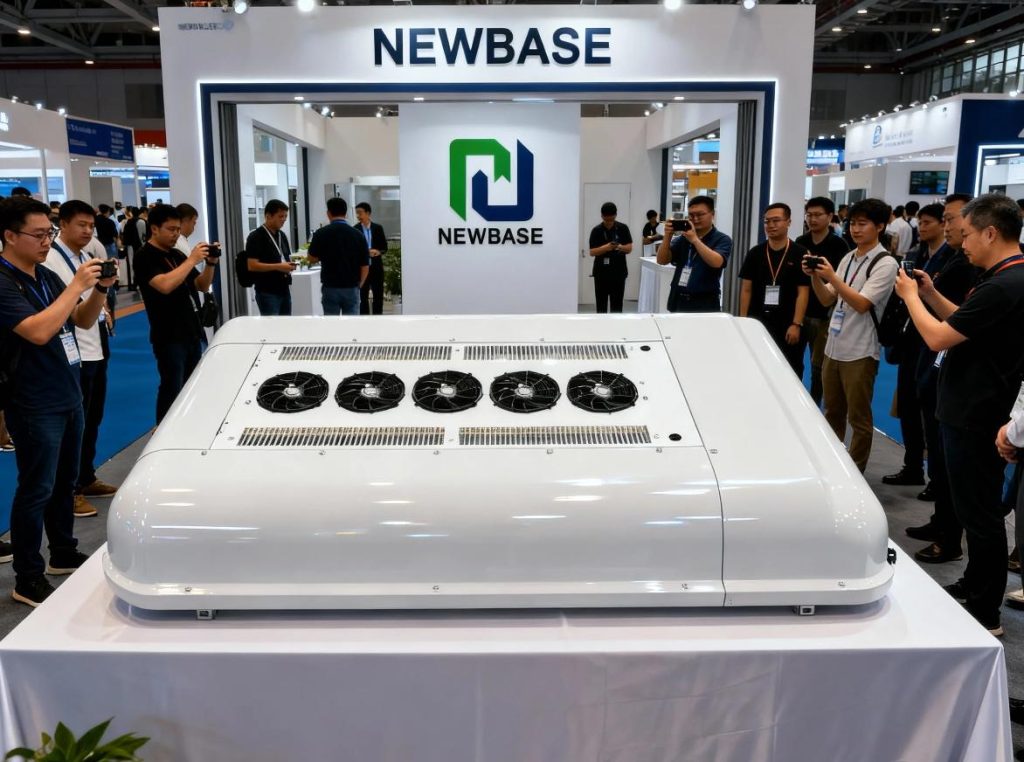

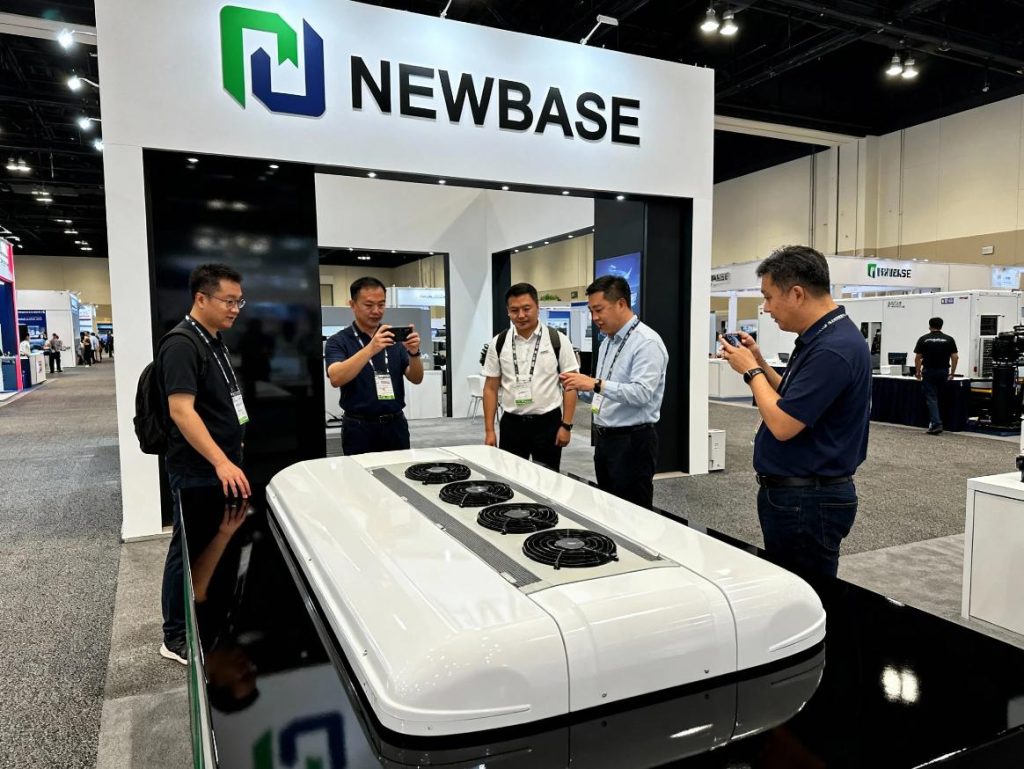

Sistema HVAC para autocarros eléctricos: Soluções avançadas para o trânsito moderno

Design de fluxo de ar optimizado por CFD

Integração da Curva de Conforto Europeia

Avanços na engenharia acústica

Controlo de Deslocamento Variável Adaptativo

Válvula de expansão eletrónica de precisão (EEV)

Gestão de energia com lógica difusa

Melhoramento a baixa temperatura

Proteção de energia multi-camada

Compatibilidade electromagnética (CEM)

Durabilidade de nível automóvel

Interface de controlo multimodal

Plataforma de nuvem habilitada para IoT

Sistema de inversor DC completo

Materiais compósitos avançados

Conceção da estrutura modular

NB-015C5A-CPY04 Módulo de potência de refrigeração 3 em 1 - Sistema de refrigeração inteligente...

Título: NB-015C5A-CPY06 Módulo de controlo térmico EV tudo-em-um -...

Unidade de refrigeração para carrinhas refrigeradas: NBESR1000A - Refrigeração avançada...

No atual ambiente de logística em rápida evolução, o controlo fiável da temperatura...

Unidade de arrefecimento para camiões refrigerados NEWBASE: Concebida para um funcionamento uniforme...

Unidade de refrigeração eléctrica para carrinhas frigoríficas: NBESR1000A - O...