3-in-1 Refrigeration Power Module

NB-015C5A-CPY04 3-in-1 Refrigeration Power Module – Intelligent Cold…

Full DC inverter heat pump air conditioner, suitable for 6 – 12m pure electric buses, hybrid buses and fuel cell buses (basic platform).

| Basic Model | NBEAC-21 | NBEAC-24 | NBEAC-30 | NBEAC-34 |

| Structural Form | Roof-mounted Integrated | |||

| Applicable Bus Length(m) | 6~7 | 7~8.5 | 9~10 | 10~12 |

| Cooling Capacity(KW) | 18 | 26 | 30 | 32 |

| Heating Capacity(Heat Pump )(KW) | 20 | 28 | 36 | 38 |

| Evaporator Airflow Volume(M/h3) | 3200 | 3200 | 4800 | 7200 |

| Condenser Airflow Volume(M/h3) | 4800 | 6000 | 8000 | 1000 |

| Compressor numbers | Single | Single/Dual | ||

| Refrigerant | R407C/410A | |||

| Size(L*W*H,mm) | 2610*1600*270 | 2500×1920×280 | 2750*1920*280 | 3000*1920*270 |

| Unit Weight(kg) | 150 | 230 | 250 | 275 |

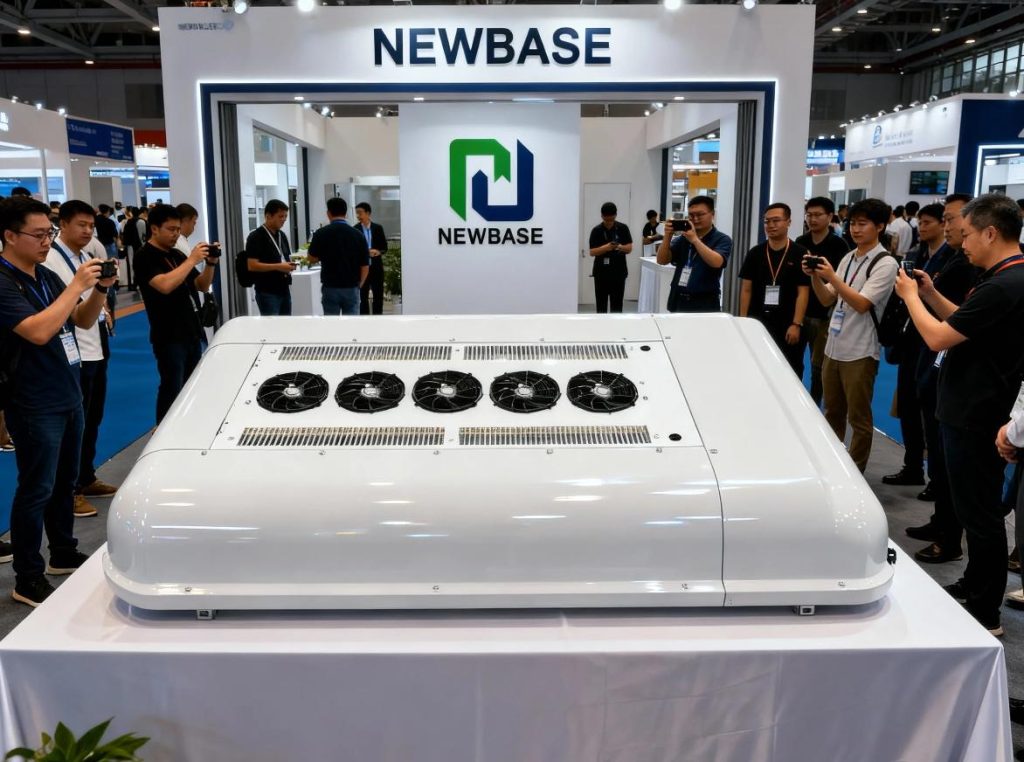

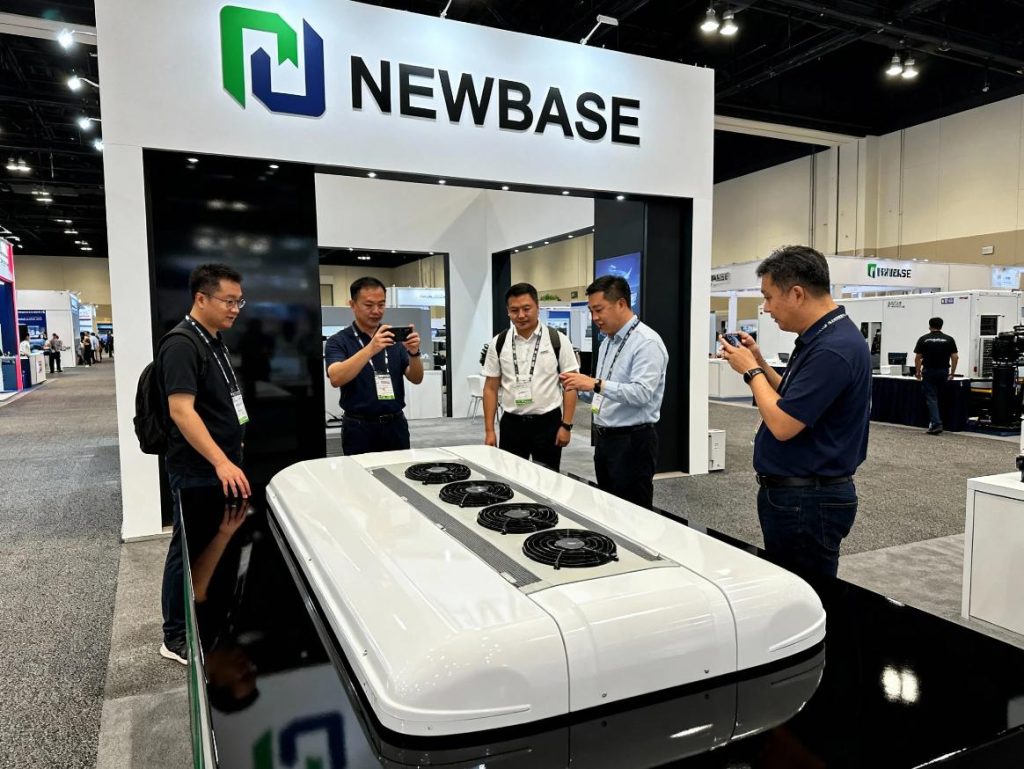

Roof-mounted air conditioning and battery thermal management system integration(compact integration)

Suitable for pure electric buses, hybrid buses, and fuel cell buses equipped with liquid-cooled batteries, meeting the needs for both air conditioning cooling/heating and battery cooling/heating.

| Basic Model | NBEAC-21-T | NBEAC-24-T | NBEAC-30-T | NBEAC-34-T |

| Structural Form | Roof-mounted Integrated | |||

| Applicable Bus Length(m) | 6~7 | 7~8.5 | 9~10 | 10~12 |

| Cooling Capacity(KW) | 18 | 26 | 30 | 32 |

| Heating Capacity(Heat Pump )(KW) | 20 | 28 | 36 | 38 |

| Battery Side Driving Cooling Capacity (KW) | 3/5 | 3/5 | 3/5 | 3/5 |

| Battery Side Charging Cooling Capacity (KW) | 5 | 8 | 8 | 8 |

| Evaporator Airflow Volume(M/h3) | 3200 | 3200 | 4800 | 7200 |

| Condenser Airflow Volume(M/h3) | 4800 | 6000 | 8000 | 1000 |

| Compressor numbers | Single | Single/Dual | ||

| Refrigerant | R407C/410A | |||

| Size(L*W*H,mm) | 2610*1600*270 | 2500×1920×280 | 2750*1920*280 | 3000*1920*280 |

| Unit Weight(kg) | 180 | 260 | 250 | 275 |

Electric Bus HVAC System: Advanced Solutions for Modern Transit

CFD-Optimized Airflow Design

European Comfort Curve Integration

Acoustic Engineering Breakthroughs

Adaptive Variable Displacement Control

Precision Electronic Expansion Valve (EEV)

Fuzzy Logic Energy Management

Low-Temperature Enhancement

Multi-Layer Power Protection

Electromagnetic Compatibility (EMC)

Automotive-Grade Durability

Multi-Modal Control Interface

IoT-Enabled Cloud Platform

Full DC Inverter System

Advanced Composite Materials

Modular Framework Design

NB-015C5A-CPY04 3-in-1 Refrigeration Power Module – Intelligent Cold…

Title: NB-015C5A-CPY06 All-in-One EV Thermal Control Module –…

Refrigerated Van Refrigeration Unit: NBESR1000A – Advanced Cooling…

In today’s fast-moving logistics environment, reliable temperature control…

NEWBASE Refrigerated Truck Cooling Unit: Engineered for Uniform…

Electric Refrigerated Van Refrigeration Unit: NBESR1000A – The…